From its early beginnings as a low-cost alternative to glass, polycarbonate has evolved into a high-performance material with numerous applications in architecture. In this blog post, we will explore the history and evolution of polycarbonate and examine its challenges and future potential in architectural design.

Development of Polycarbonate

Polycarbonate is a highly durable and versatile plastic material that has been used in a wide range of applications for over half a century. It was first developed in the 1950s by a team of researchers at General Electric, who were looking for a substitute for glass in aircraft canopies. Since its’ early development, polycarbonate has become a popular choice for a wide range of applications due to its high impact resistance, clarity, and heat resistance.

Polycarbonate has evolved significantly, with new formulations and manufacturing techniques making it even more versatile and adaptable for various industries. Today, it is widely used in architecture and construction. Its evolution has been driven by the need for more durable and sustainable building materials, as well as advancements in technology and manufacturing processes. Today, there are grades of polycarbonate that are more eco-friendly, such as those made from bio-derived materials or recycled plastics.

Different Polycarbonate Grades and Performance

Each grade of polycarbonate has unique properties and characteristics that make it suitable for different applications. For instance, there are grades of polycarbonate that are highly resistant to impact, heat, and UV radiation, making them ideal for outdoor and high-performance applications. These are typically used in architecture and construction.

The manufacturing process for polycarbonate has evolved considerably. While the original process involved the use of highly toxic and flammable solvents, modern production methods rely on more environmentally friendly processes that use water-based solvents instead.

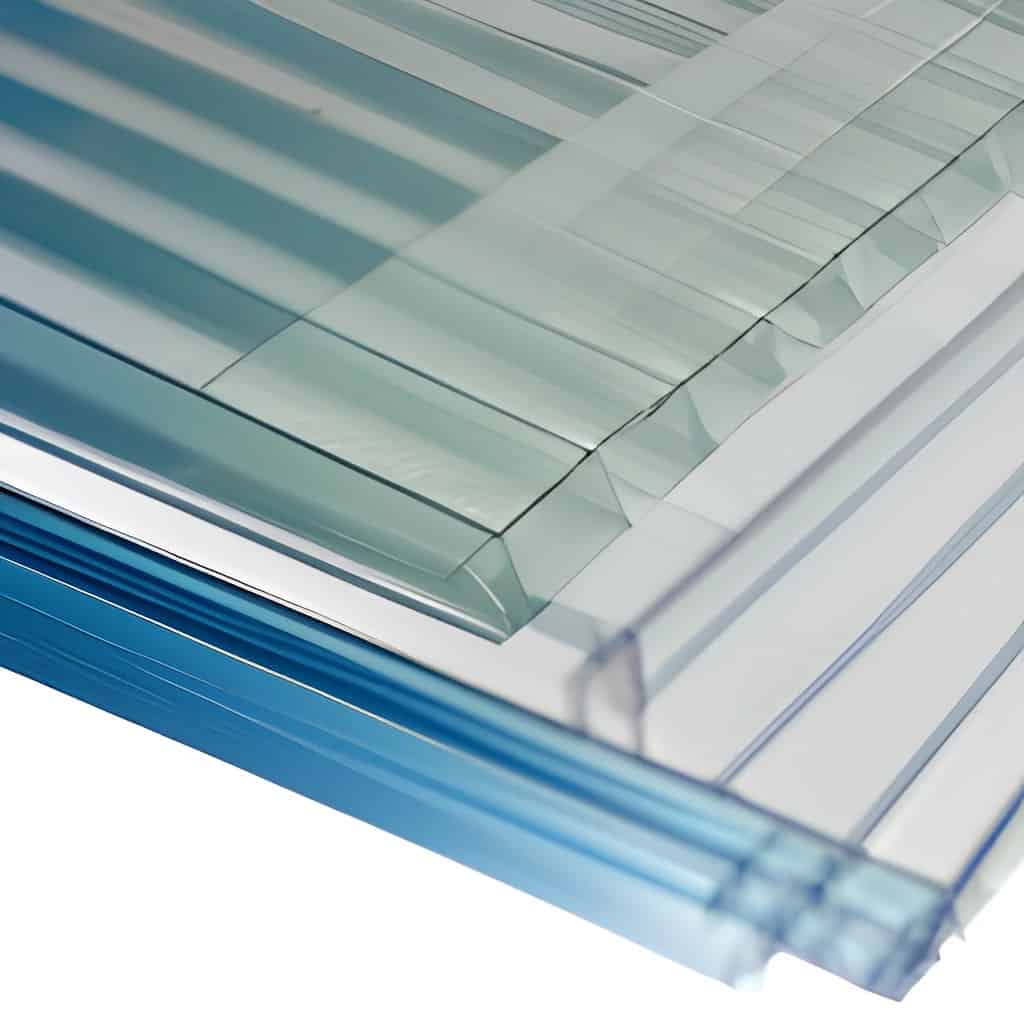

Multiwall Polycarbonate Panels

One major change to polycarbonate has been the development of multiwall panels. These panels, which are made up of two or more layers of polycarbonate separated by air spaces, offer improved insulation and structural strength. They are commonly used in glazing applications, providing excellent light transmission while also reducing heat loss and increasing energy efficiency.

Another important innovation has been the introduction of UV-resistant coatings, which protect polycarbonate from yellowing and degradation caused by exposure to sunlight. This has extended the lifespan of polycarbonate products and made them more suitable for outdoor use. The co-extrusion of UV-resistant coatings can be applied to both the interior and exterior of a polycarbonate sheet. This co-extruded UV-resistant layer eliminates the need for UV protective maintenance coatings, which are often required by other glazing materials.

Design Options & Versatility

In addition to its durability, sustainability, and performance benefits, polycarbonate also offers architects and designers a range of aesthetic options. The material can be tinted or coated to achieve different colors, textures, and levels of transparency. It can also be molded, extruded, and thermoformed into a variety of shapes and sizes, allowing for creative and unique designs.

One of the most appealing features of translucent polycarbonate wall systems is their ability to let natural light into a space while still providing privacy and insulation. This is especially useful for buildings that require a balance of natural light and privacy, such as hospitals, schools, and office buildings. As a result of its many benefits, polycarbonate has become a popular choice for building facades, skylights, canopies, and other architectural elements.

Applications of Polycarbonate Systems

Greenhouses and Skylights

Benefits of using polycarbonate in greenhouse construction:

- Lightweight yet extremely durable

- Provides excellent insulation, reducing HVAC loads

- Blocks harmful UV rays while still allowing sunlight to enter

- Cost-effective alternative to traditional glass

Different types of polycarbonate sheets for skylight applications:

- Clear or translucent sheets allow natural light into buildings

- Tinted or colored sheets provide shading and reduce heat gain

- Textured or patterned sheets offer privacy and visual interest

Commercial Buildings

Some of the benefits of using polycarbonate in commercial buildings (exterior or interior walls) include:

- Lightweight yet strong construction

- Excellent thermal insulation properties

- UV-resistant surface that doesn’t yellow or degrade over time

- Cost-effective alternative to glass

- Easy to install due to its lightweight nature

When compared against glass, polycarbonate has proven itself as a superior option for architects looking for high-performance glazing systems. It has better impact resistance, which allows it to withstand harsh weather conditions with ease. Additionally, it’s easier to shape than glass which provides tremendous opportunities when it comes down to creating complex designs.

Innovative uses of translucent polycarbonate panels in façade design have exploded recently because they provide an elegant way of introducing light into spaces while retaining privacy at the same time. These panels are now being used in modern architecture projects worldwide as designers look for ways of harmonizing their structures with the environment around them without sacrificing aesthetic appeal or performance.

Innovative Uses in Modern Architecture

Design possibilities with colored and textured polycarbonates offer architects a unique way to create stunning visual effects, while also providing functional benefits such as light transmission and durability. The endless color options available with this versatile material can be used to enhance branding or create an eye-catching façade. In addition, the texture of the polycarbonate panels can add depth to a building’s design.

When lit from the interior, translucent polycarbonate walls take on an entirely new appearance at night. The gentle light diffusion of the polycarbonate provides a glowing appearance, adding appeal and interest without changes to the design.

Polycarbonate panels also make a great canvas for backlit designs. Adding lighting behind polycarbonate walls, canopies, or screens can showcase a brand or business’ signage and elevate the space to become a beacon of its community.

Sustainability of Polycarbonate in Architecture

As sustainability becomes increasingly important in architecture, there is a growing demand for environmentally friendly materials like polycarbonate. The material can be recycled and reused which makes it an attractive option for architects looking to create sustainable buildings while also reducing costs.

Durability and Maintenance

Polycarbonate’s durability and low maintenance needs make it a popular choice for building projects. Manufacturing techniques and factory fabricated systems further improve the strength and cost. Polycarbonate panels have high impact resistance, making them ideal for areas that experience harsh weather conditions or potential impacts.

Here are some additional points to keep in mind when considering the durability and maintenance of polycarbonate:

- Be sure to consult with your supplier or manufacturer on recommended cleaning methods

- Regularly cleaning the surface of polycarbonate panels can help prolong their lifespan and maintain their appearance

- UV-resistant co-extruded polycarbonate eliminates the need for protective coatings, lessening maintenance

Sustainability and Environmental Impact

Comparing the carbon footprint of polycarbonate versus other building materials is essential when considering the sustainability and environmental impact of a project. While it may initially seem that polycarbonate has a larger carbon footprint, studies have shown that it actually compares favorably to other common building materials like glass and aluminum.

Recycling options for end-of-life polycarbonate products are also crucial in promoting sustainable use. Polycarbonate can be recycled into new products or repurposed, reducing waste and overall environmental impact. Additionally, LEED certification plays a significant role in promoting sustainable use of polycarbonates by recognizing projects that incorporate environmentally friendly practices such as the use of recyclable materials like polycarbonate.

- Polycarbonate compares favorably to other common building materials

- Recycling options reduce waste and environmental impact

- LEED certification recognizes sustainable practices

Looking Ahead – Future of Polycarbonate

Today, polycarbonate continues to evolve as a material, with research focusing on enhancing its properties even further. Scientists and researchers are exploring ways to improve polycarbonate’s properties and develop new grades that can meet emerging industry needs. This has led to the development of polycarbonates with enhanced flame retardancy, biocompatibility, and scratch resistance. They are also exploring ways to improve its optical clarity and develop polycarbonates that are more biocompatible for medical applications. As technology advances, it is likely that polycarbonate will continue to be a go-to material for many applications across various industries.

As the demand for sustainable and energy-efficient building materials continues to grow, polycarbonate is likely to remain a key player in the construction industry. Its evolution over the years has made it a reliable and versatile material that can meet the needs of architects and builders across a range of projects. By keeping up with the latest innovations and advancements in polycarbonate technology, architects can continue to push the boundaries of what is possible in modern building design.