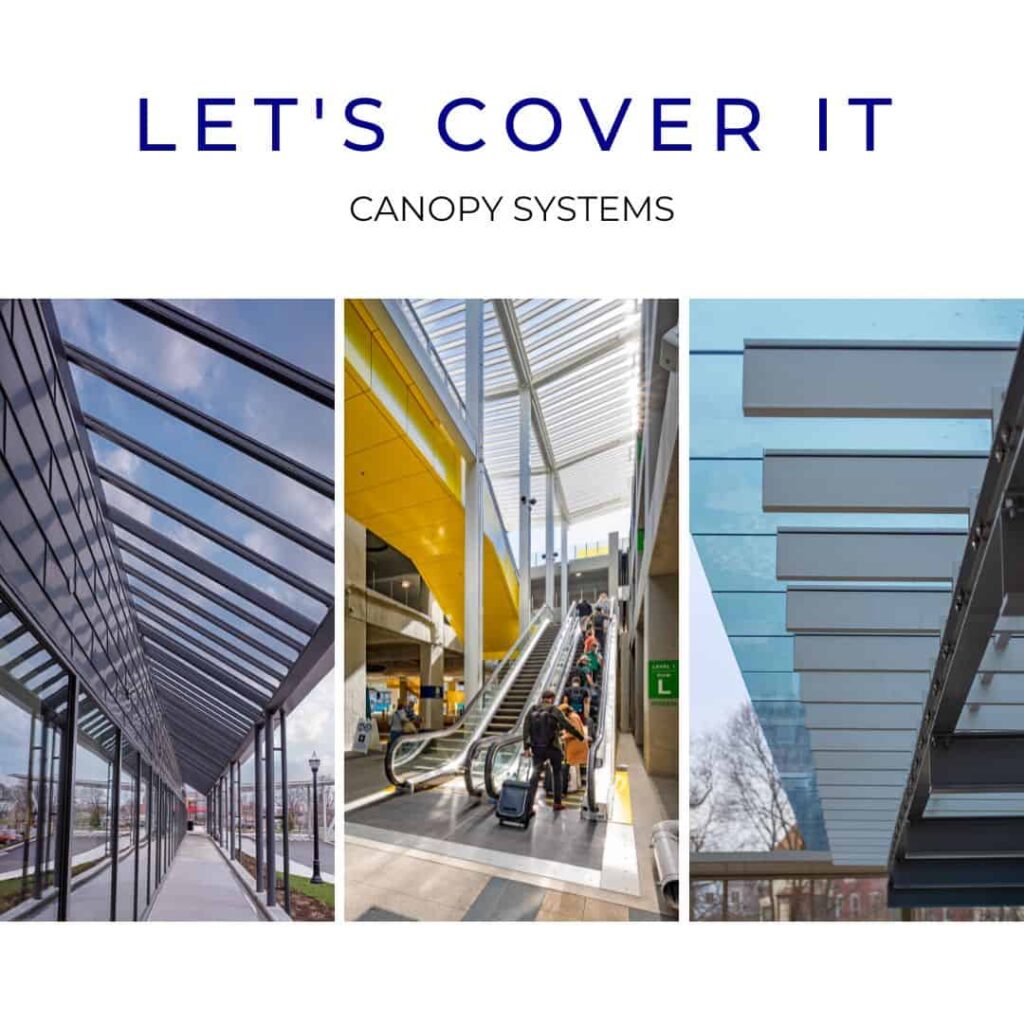

Canopy systems function as an important element of building exteriors and public spaces. Historically, canopies were used at religious spaces and churches, covering sacred artifacts such as tombs, altars, and statues.

Aside from shelter, shading, and curb appeal, canopy systems have a wide range of benefits to building occupants and owners. When tied into a building design, canopy systems can define an entrance and be integrated into wayfinding.

Courtyard canopies can serve as a focal point for recharging and relaxation, boosting wellbeing of building occupants. Daylighting has been proven to have benefits in office spaces, schools, and workplaces and canopy systems can aid in providing usable outdoor space.

Standalone canopies can be used as gathering places for transit riders to take shelter and aid in safety when lit at night. They can also help designate spaces as transit stops and be integrated with wayfinding signage.

Restaurants, recreational facilities, and retail may benefit from additional usable space provided by canopies, especially in inclement weather. Using commercial canopies can contribute to LEED buildings through daylighting and recycled content.

When specifying a commercial canopy system, there are many questions to consider, including:

What shading/daylighting is desired?

What is the function and application of canopy system?

Is it freestanding or attached?

What is the budget?

Will an existing structure be used, or does the project require structural support?

What are the aesthetic goals? Slope? Curved or special shapes?

Qualified canopy system manufacturers can aid with understanding code requirements, system performance, and assist with choosing a system that meets all the project goals. All canopy systems should include weepage systems for weather and condensation control. In addition, canopy systems should be factory fabricated to achieve maximum performance.

Types of canopy systems and typical applications

Glass Canopies

Many architects and building owners prefer the appearance of glass canopies. They don’t interfere with the building design and have a sleek appearance.

The tradeoff with glass canopies typically is a higher cost than other materials.

Available in up to 12’ spans, glass canopy systems can include cantilevered glass, and self-supporting aluminum rafters (3”, 5” or 8” deep typically). Glass coatings and silk screens can offer more shading if desired.

Monolithic Canopies – Monolithic Polycarbonate

For those who are searching for a glass-like appearance at a lower cost, monolithic canopies can be an ideal alternative. Monolithic polycarbonate is as clear as glass, half the weight, and offers more impact resistance.

While less expensive than glass, monolithic canopies are typically more expensive than multiwall cellular polycarbonate. This is due to the greater amount of resin required in the manufacturing process.

Canopy systems can accommodate monolithic sheets up to 12mm (½”) thick. Wind load and deflection is enhanced, and further spans are possible with systems that can incorporate thicker monolithic polycarbonate. Monolithic systems (like all polycarbonate systems) are UV resistant and come in a variety of colors, offering varying degrees of light transmission and solar heat gain.

Standing Seam Canopies – Cellular Polycarbonate

Standing seam canopies are an economical alternative to glass and monolithic canopies. Standing seam canopies use 16, 20, or 25mm standing seam cellular polycarbonate and may include continuous battens or mullions that hold the glazing in place. Framing systems and gasketing are designed to accommodate thermal movement of thermoplastics.

Standing seam canopies with battens eliminate the need for vertical mullions. Panels up to 39’ long are joined together with aluminum clips, then a batten and end cap are applied. Standing seam canopies with battens can be cold formed to a radius for curved applications.

Canopies with continuous clamping mullions are long spanning, designed for continuous runs up to 54’ long without horizontal mullions. They can be used as overlay systems attached to existing framing or with aluminum rafters (3”, 5” or 8” typically).

Standing seam polycarbonate panels are available in many different colors, which produce different U values and LT%. A popular glazing choice, opal, provides a LT% of approximately 29-38% for 20mm standing seam panels. Conversely, clear panels offer approximately 35-58% (dependent upon IR/UV Matte, or AR treatments).

Self-Supporting Canopies – Glass or Cellular Polycarbonate

Self-supporting canopies feature rafters (2”, 3” or 6” typically) for medium to long spanning conditions. The system is pressure equalized for water control and superior air and water performance.

Designed for versatility, these canopies fit projects that are looking for glass (up to 1” thick) or polycarbonate flat sheet (10, 16mm, or 25mm flat sheet typically). These systems can also be used as skylight systems.

Self-supporting canopies feature condensation and water control gutters—ideal for large canopy applications. They can be curved down to a 4’ radius.

Overlay Canopies – Glass or Cellular Polycarbonate

Overlay canopies are ideal for existing systems that need upgraded glazing, or where an existing substructure is in place. They do not contain structural elements, but rather shallow rafters intended to be placed over structural rafters.

Overlay canopies accept glass (1/4” to 1” thick) or polycarbonate flat sheet (16mm or 25mm flat sheet typically). Available in multiple colors and translucencies, overlay canopies adapt to the existing structure and your specific needs.

Final thoughts

When specifying a canopy system, one of the biggest final considerations is factory fabrication. A system that achieves optimal performance needs to be built and installed properly. Working with an experienced manufacturer and installer is vital — for both the longevity of the system and protection of the end user.