Prior to the availability of structured polycarbonate panels, EXTECH used Fiberglass Reinforced Panels (FRP) in our daylighting systems. When cellular polycarbonate came on the scene, we gave it a try - and quickly realized how superior it is to FRP. EXTECH began specializing in the use of cellular polycarbonate for daylighting solutions, and we never looked back – a decision that has proven prescient and valuable.

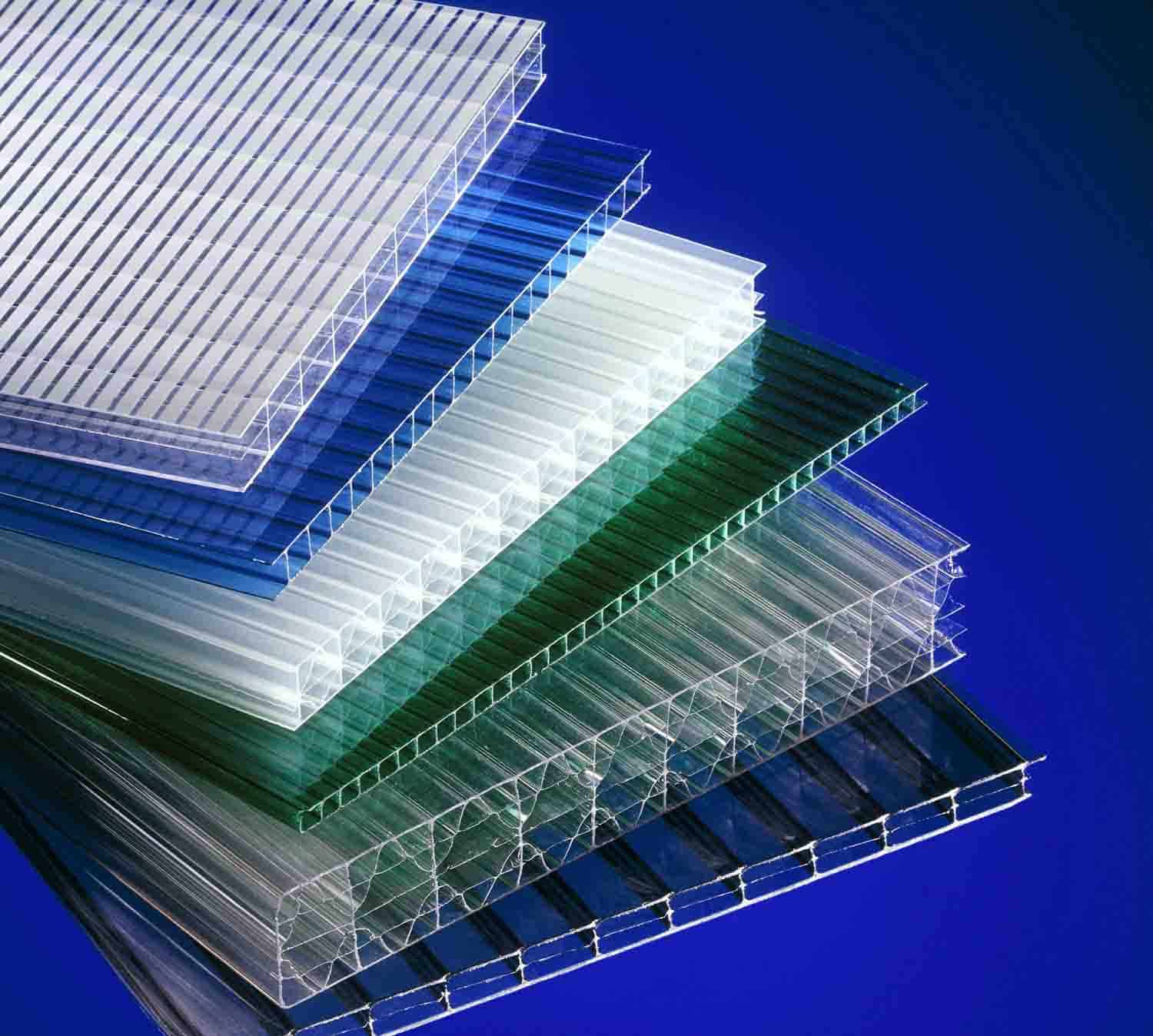

The benefits of this versatile and environmentally-friendly product are unsurpassed in terms of quality and function for walls, windows, skylights, canopies, and interior projects. Polycarbonate is delicate enough to transmit light while possessing the durability to withstand hurricane-blown debris. It isn’t affected by “fiber-bloom,” a deterioration that happens in FRP (see below photos for example). Polycarbonate is also resistant to yellowing, another symptom of aging FRP. Polycarbonate can be used with a wide range of applications, from industrial structures that demand resilience to cultural institutions that prefer soft, ethereal aesthetics.

Other advantages include:

- Highly insulating

- Light-weight panels install quickly for reduced installation cost

- Protects against UV rays and delivers solar shading

- Diffuses light, providing a soft glow without glare; glass beads can be added to the resin to deliver an enhanced glow

- 100% recyclable; utilization can count toward LEED certification

- Superior alternative to Fiberglass Reinforced Panel (FRP) because of FRP’s tendency to result in "fiber-bloom" (see below photos)

- Resistant to yellowing as it ages, an issue with FRP

- Good alternative to glass, which is prone to breakage, and heavy (making it hard to install)

- Extremely durable; tested and designed to deliver impact resistance for use in coastal structures affected by hurricanes

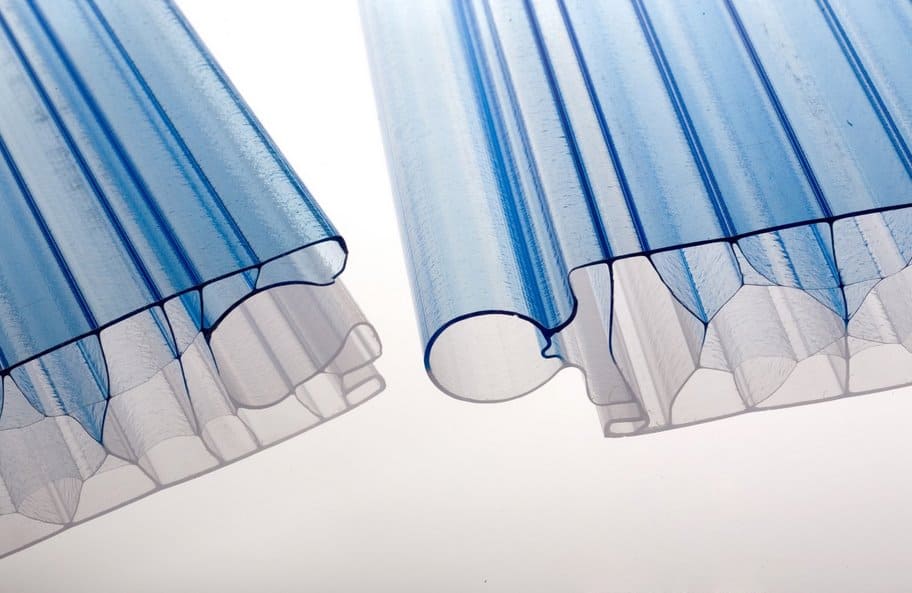

- Available in various colors and translucencies

- Especially effective for retrofits

- Less expensive than glass

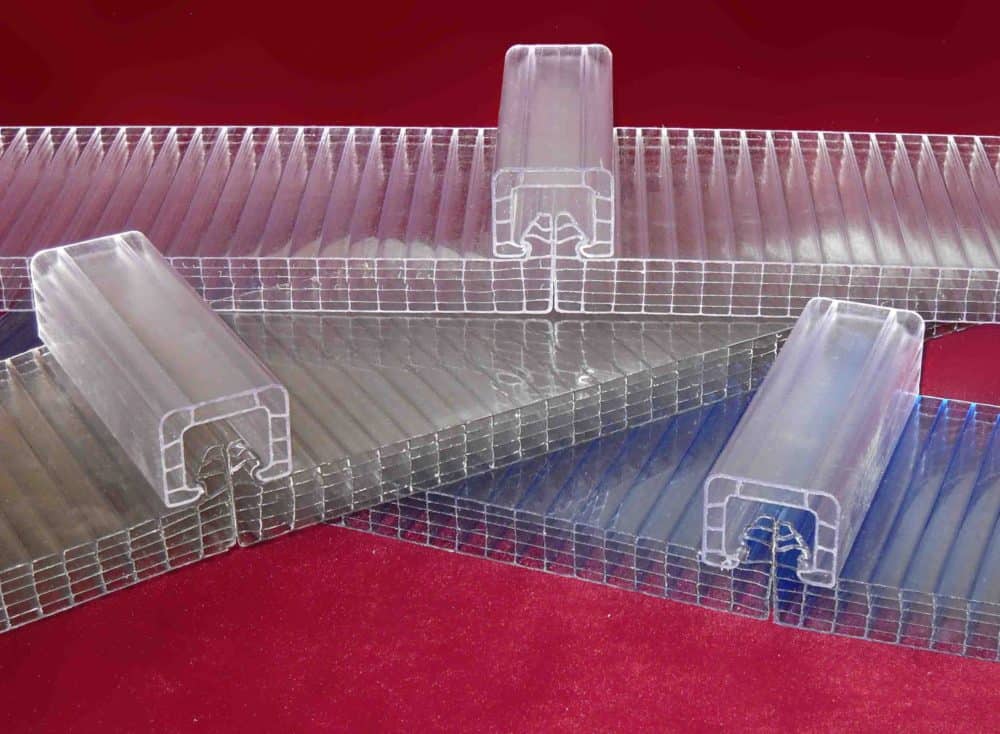

- Unlike glass, polycarbonate can be cold-formed to various radii to create curved applications

- Available in ASTM E-84 Class A, CC-1 fire rated material

Though we specialize in the use of cellular polycarbonate, our systems can also accept glass. The EXTECH team is ready to answer all your questions on daylighting and the options available – please contact us to find out more!

"Fiber-bloom" is a deterioration that is common in Fiberglass Reinforced Panels (FRP) and can happen within 10 years of an application's construction. Many of our retrofits are done on buildings that originally used FRP but had to be replaced with polycarbonate due to yellowing and a diminished daylighting capacity. Fiber-bloom is one of the many reasons EXTECH does not use FRP.

Sheeting

The four main types of sheeting we offer with our systems are Standing Seam, Interlocking, Monolithic, and Flat Sheet. Each type offers its own unique advantages, described below; all four provide the benefits described above.

Standing Seam

- Panels can be as long as 54 feet; standard panels come in widths of 24 inches wide

- Horizontal framing delivers deep glazing rabbets, which improve impact resistance

- Framing also delivers low-friction gaskets, lengthening the lifespan of the sheeting system

- Clips and battens used in the framing come in a variety of colors and finishes

- Have been subjected to a complete battery of air, water, and structural testing

- Typically used in horizontal structures, like canopies

- Panels come in a variety of colors

- 100% recyclable

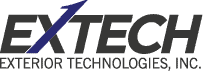

Interlocking

- Panels can be as long as 54 feet; standard panels come in widths of 19 5/8 inches wide

- Tongue-and-groove joinery does not require vertical framing, thus delivering a sleek look and requiring less hardware

- Panels have insulation value of up to U-0.25 (R-4) for 40mm thickness

- Has been subjected to a complete battery of air, water, and structural testing

- Used for vertical applications, like walls

- Panels come in a variety of colors

- 100% recyclable

Monolithic

- Panels can be as long as 54 feet; standard panels come in widths of 24 inches wide

- Typical thickness is 1/4 inch

- Panels are solid, unlike the other types which are multi-wall

- Panels come in a variety of colors

- 100% recyclable

Flat Sheet

- The most economical of the four types

- Does not use any framing while still delivering sufficient durability and solar shading for particular structures

- Panels can be as long as 54 feet; standard panels come in widths of 24 inches wide

- Can be used vertically or horizontally, and is typically used for utilitarian structures like greenhouses and maintenance enclosures

- Panels come in a variety of colors and shapes

- 100% recyclable