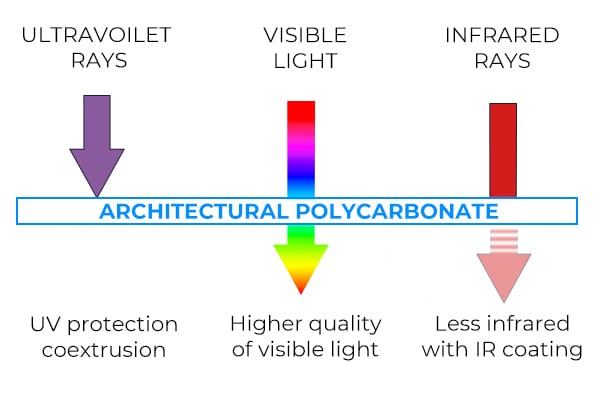

Retrofitting with polycarbonate systems can extend the lifespan of a building’s exterior envelope, reducing maintenance and replacement costs in the long run. They can be used to improve the energy efficiency of buildings, by providing excellent thermal insulation properties, reducing heat transfer through walls and roofs. By installing polycarbonate systems, building owners can decrease their reliance on heating and cooling systems, leading to lower energy bills over time.

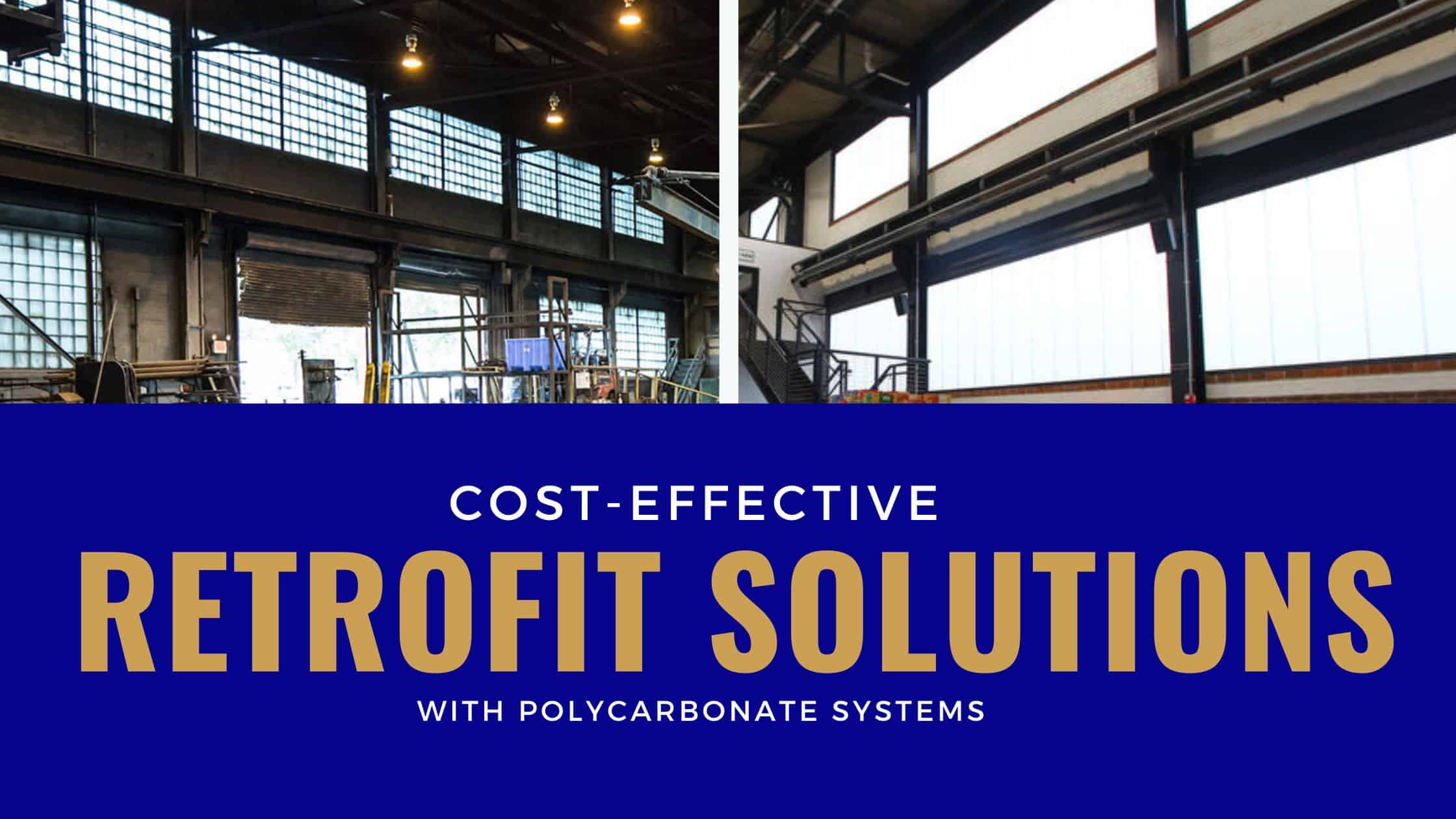

Overglazing or Total System Replacement?

An important distinction to make when replacing a traditional system with a polycarbonate one is that rabbets of traditional framing systems often cannot be used with polycarbonate systems. Polycarbonate systems must include controlled pressure gaskets, and a low-friction treatment. The system must allow for thermal movement of polycarbonate and include a framing system that can weep water away for a tight weather seal.

One option is to replace the entire system with a polycarbonate system. The existing framing can sometimes be used as the existing support structure or can be replaced all together.

An example is a skylight retrofit of the MTA in Bronx, NY. The existing skylights were emitting so much solar energy and glare, that they were temporarily painted black. It was clear that painting the glazing wasn’t a permanent fix.

The solution was to install replacement polycarbonate skylights, which featured 25mm opal cellular polycarbonate. They were able to achieve 27% light transmission and .37 solar heat gain coefficient, allowing maintenance crews to work comfortably with ample daylight. The skylights provide enough light to replace the need for overhead lighting in those strategic skylight locations.

Overglazing with polycarbonate systems can be a cost-effective solution for improving the energy efficiency and aesthetics of existing buildings. Overglazing involves installing a layer of polycarbonate panels over existing windows or glazing to enhance thermal performance, natural light transmission, and durability.

Polycarbonate skylights and walls are ideal for overglazing because they are lightweight and do not add much to need additional support. In a skylight overglazing project in Los Angeles for a Boys & Girls Club, adding the cellular polycarbonate overglazing system only increased the overall weight by about 0.05 kPa (1 psf). This was not enough to affect the steel support structure below, proving to be a cost-effective solution. In addition, labor costs were reduced by only adding to the existing structure, without removing the original framing and glazing system.

Testing & Warranty

Polycarbonate glazing typically includes a 10-year warranty for colorfastness, hail damage, and loss of light transmission. In addition, the framing finish carries a 10-year warranty, and each system is backed by an overall manufacturer warranty for deterioration and leakage.

Polycarbonate systems are tested to many standards, including the following:

AAMA E 283, Air Infiltration

AAMA E 330, Structural Strength

AAMA E 331, Water Infiltration

ASTM D-2244 Color Change

ASTM D-1925 Yellowing Index

ASTM D-1003 Light Transmission

NFRC: U-Value

Other tests, such as ASTM D-635, ASTM E-84, ASTM D-1929, and ASTM D-2843 are used to determine resistance to fire or smoke generation.

Retrofitting buildings with polycarbonate systems can offer numerous benefits, including energy efficiency, natural light, durability, versatility, and cost savings. When considering retrofit options, it’s essential to evaluate the specific needs of the building and the desired outcomes to determine the most suitable solution.