Glass skylights can provide many benefits when installed in commercial buildings. There are various criteria to consider when planning a glass skylight installation; however, we’ve highlighted the five points that we believe are the most commonly overlooked.

While a successful glass skylight installation involves the culmination of efforts by an experienced team, considering the following items in the early stages of project development can help get your skylight installation in the right direction.

Glass Skylight Product Specification

A successful installation begins with selecting the appropriate product for the application. Most glass skylights are fabricated with aluminum frames that come with a variety of options. However, in applications where the skylight is above conditioned space, thermally improved frames are recommended. These specially designed frames reduce the transfer of unwanted thermal energy into the built environment; thus, reducing overall energy consumption.

The type of finish used on the skylight frame also needs to be considered. Metal skylight finishes can range from anodized finishing to high-performance PVDF resin-based coatings. For aesthetic purposes, the interior framing of the skylight painted to match the built environment is often preferred. In these cases, baked enamel coatings can be used as a feasible value engineering solution. In addition to offering numerous color options, these cost-effective coatings are ideal for the less demanding interior environment, while the exterior can be finished with a higher performance coating.

All glass skylight systems should also be engineered and tested to resist the applicable project loads, including wind, snow and dead loads. Working with an experienced glass skylight manufacturer will ensure that all these requirements are met.

Skylight Installation Coordination

When planning a glass skylight installation, the timing of activities performed by all related trades should be carefully coordinated. Roofing contractors, skylight installers, and manufacturers must work together to achieve a successful, leak-free installation.

Proper coordination helps to avoid installation errors, delays, and eventual cost overruns. EXTECH provides professional engineering and project management support to installation crews to help ensure project success.

Glass Skylight Curbs

The curbs are the primary interface between the roofing system and a glass skylight. They must be high enough to prevent the infiltration of large volumes of rainwater through the skylight. Curbs can be constructed of wood or metal and can be built on-site by a roofing contractor or prefabricated by a glass skylight manufacturer. Prefabricated curbs are, however, recommended due to their sturdy and durable construction which consists of heavy gauge metal and factory installed insulation.

Crickets for Steep Slope Skylights

A “cricket” is a diverter used on steep slope roofs at the head of the skylight. Their primary purpose is to channel water around the skylight. Crickets can also help prevent the build-up of debris that can accumulate moisture and eventually lead to rot in wooden curbs or degradation of sealants around the skylight. For steep slope applications, where the skylight does not extend to the ridgeline, the installation of a cricket should be strongly considered.

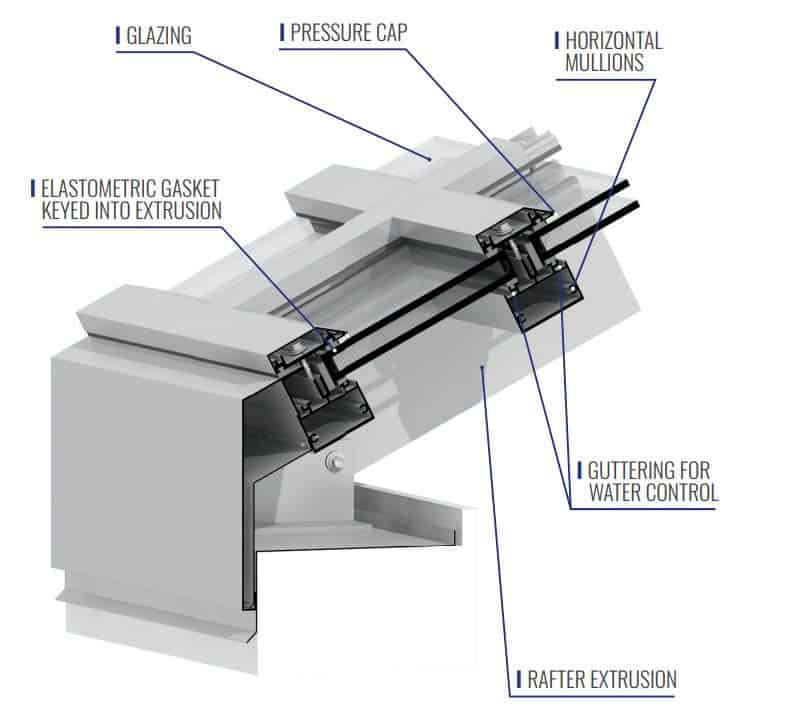

Internal Guttering

EXTECH’s glass skylight systems have internal guttering that keeps condensation, or even water that infiltrated past the primary seals, from dripping on building’s interior. When installing internally guttered skylight systems, fastener placement and installation should be done in accordance with the installation drawings. Improperly placed fasteners can pierce the internal gutter and cause potential leakage issues.

For over 50 years, EXTECH has been producing commercial and industrial glazing for a wide variety of industries. During our experience, we have seen and overcome numerous glass skylight application challenges. Should you have any questions regarding the above considerations, EXTECH’s team of skylight designers and engineers would be pleased to assist you; feel free to contact our support team today.