The framing on the daylighting system you choose can result in long-lasting value -- or a full-on catastrophe. EXTECH's General Manager Jim Leslie recounts a cautionary tale and outlines what you need to know to ensure the daylighting in your design will deliver lifelong durability, cost-savings, and beauty.

It happened again.

A contractor recently came to us with an urgent retrofit on his hands: an office building needed to replace skylights and a translucent wall because of persistent leakage. Not only were the systems leaking, but the glazing was popping out of the framing and water penetration had caused the panels to darken, further diminishing the little daylighting they provided. The decayed glazing also made the building look blighted and abandoned, and it was not delivering the insulating value that it should have been. The building owner was looking at substantial repair costs on a facility that was built only 15 years ago.

We met with the building owner and contractor to assess the issues. We offered solutions, consoled the building owner over the repair costs, and explained what had gone wrong.

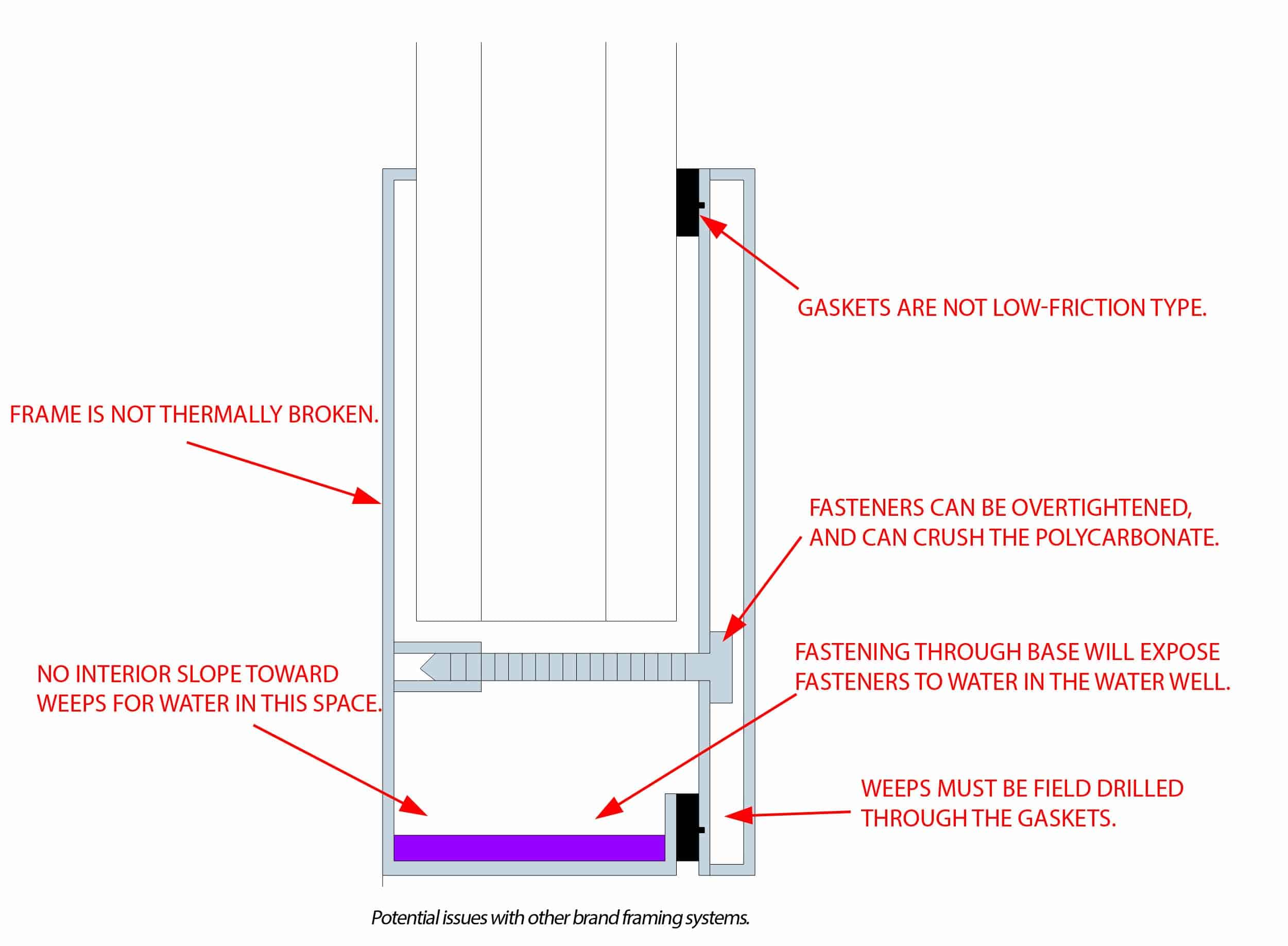

“See the head gaskets?” we asked. “The reason the glazing is coming loose is because these aren’t low-friction gaskets – they don't properly accommodate the thermal expansion of the glazing, and the increased friction caused them to pull out of the framing. Plus, there’s no setting block – if there was, then condensation wouldn’t have gotten into the panels, and you wouldn’t have the darkened look that you see now.”

After pointing out all the ways the framing had failed, and outlining how EXTECH’s systems are designed to prevent all these seen failings, the owner’s mood seemed to improve. Though he would have to invest more into his building than originally anticipated, he understood that our systems were deliberately engineered to prevent the leakage, glazing deterioration, and aesthetic blight he’d been grappling with since the facility was built.

So what “happened again”? This is not the first time we have been asked to retrofit a building that was originally built with inferior daylighting systems. We get a handful of projects like this every year, and the building owners are often confused as to what went wrong – they wonder if it was a bad install, or cheap glazing materials, or unexpectedly inclement weather. Though sometimes those reasons are the root causes, typically these breakdowns in daylighting systems are due to under-designed framing systems.

Time and again, we’re confronted with the myth that daylighting systems are created one in the same. Our competitors like to argue that they use the same glazing as we do, thus their systems offer the same benefits as ours. They also like to market cheaper systems and claim that there are no marked differences between our products and theirs. But there are vast and marked differences between EXTECH systems and others on the market, and it’s these differences that can make or break your design. When inferior systems are used, it degrades the lifespan, look, and performance of the application; it also allows polycarbonate – one of the most economical, impact-resistant, and insulating forms of glazing – to deteriorate.

Before specifying or buying a translucent wall, skylight, canopy, or window, check to make sure the system is engineered to address the following:

1. The Gaskets

Ensure your daylighting system uses gaskets with a low-friction surface. If gaskets are not glued into well-designed gasket tracks, and if they do not have low-friction surface materials, then they will become disengaged over time as the glazing expands and contracts. When disengaged, the glazing comes loose from the framing, causing leakage and panel decay, and compromising the structural integrity.

2. A Panel Setting Mechanism

You want to be sure any wall, skylight, or canopy system contains a mechanism for the glazing panel to sit on, such as a setting fin or setting blocks. These are necessary to keep the glazing panels from falling to the bottom of the sill profile, and thus making them vulnerable to water penetration, interior condensation, and decay. Sometimes, manufacturers forego this component, but it is essential for robust system performance.

3. Refined Components (because less is more)

Systems with precise engineering that steer clear of excessive hardware are always preferable to overly complex framing systems. Minimalist design cuts down on the time and cost of installation, and it also limits chances for human error and system failures, such as a compromised weather seal and faulty water weepage.

4. Pre-Fabricated Systems

Choosing pre-fabricated systems is the best way to ensure quality control and avoid installation delays. Many daylighting manufacturers don’t bother with pre-fabrication – instead, they rely on the installers in the field to fully understand how the systems are engineered, and then field drill the weep holes, miter corners, insert gaskets, etc. in an uncontrolled environment. Precision is difficult to achieve when at the mercy of strong winds, sun glare, and other environmental factors. This is also a huge potential liability for installing contractors.

There are other issues that mean the difference between a successful daylighting system and an inferior one, but this is a good basic checklist for choosing a daylighting supplier. When specifying or reviewing a bid, make sure you consider these factors if you want the daylighting in your design to have long-lasting value and beauty.